The window machine industry or window door machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

This windows machinery industry traditionally belongs to the heavy industry. Nowadays, many smaller companies in this window door machine branch are considered part of the light industry. Most manufacturers in the machinery industry are called machine factories, but not every machine manufacturer can manufacture good machines! Why? Because you need the right tools to manufacture machines with high quality. If somebody buy cheap chinese machines from China, it is possible to work one year with a new manufacturing line after one or some years you need to change your manufacturing line. We as Baertec Machine are manufacturing high quality machines scince 40 years, means scince 1973 and we are happy to have customers which bought machines from us 40 years ago, until today they are working with the same machines.

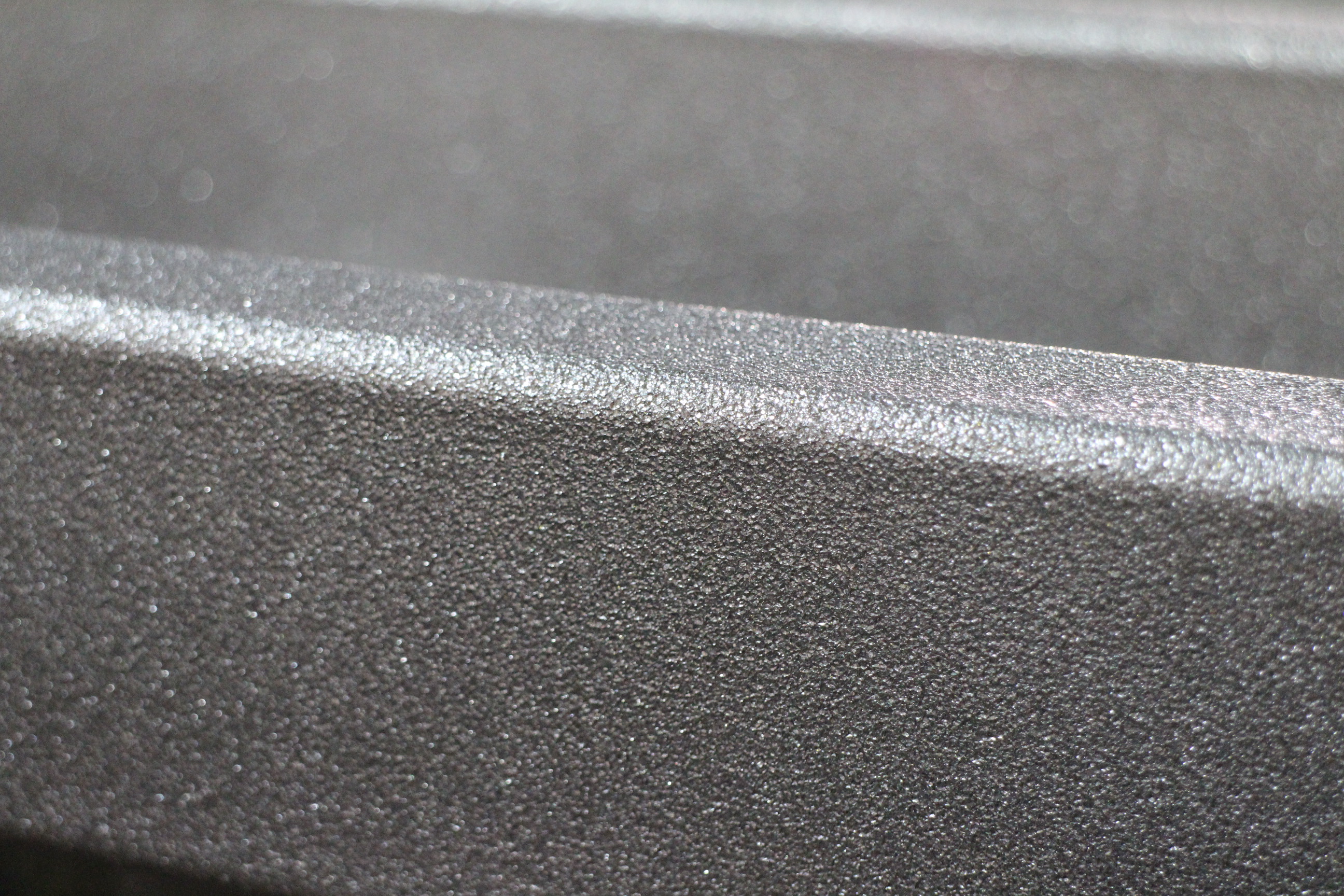

We as Baertec are the first windows machinery manufacturer in Turkey. Our heavy machines like double head with 4 metre length or our special series 6 metre length double head processing machine or assambly tables go trough or heat treatment process. What means heat treatment? After the welding process to put the machine body together there will be a stress effect on the machine steel, than it is possible that your steel profiles can bend with time from himself like a Banana this happening because the welding stress effect. Here we put the machine bodys in our special heat treatment rooms with 800 degree temperature for two days, that means in our machine language normalize process of steel and we take the stress outside of the steel if needed we can put the machine bodys in our second room for sand blasting.

Of course this is a very expensive process and not everybody is able to manufacture windows machinery like that. That means only Baertec is providing his dealers and customers self manufactured machines in special sizes and with heat treatment and sand blasting process, but is that enough to manufacture high quality with a big heat treatment room and a sand blasting room? Of course not, Baertec Machine put his 6 metre long double head cutting machine bodys in a 7000 mm x 3000 mm full automatic CNC machine for the surface milling (cleaning)and drilling (hole opening) process. A lot of different companies do that process by eyes and hand, which assure mistakes from the beginning to the end. The right head of the machine body which moves to the left and right will leaves the steel tiring if you do this process by eyes and hand, we assure you that calibration problems of the right head and 0.1 mm tolerance by the cutting and welding results are pre-programmed if you do not make this process by CNC machining.

People makes the different and Baertec Machine montage workers have more than 40 years experience. We are proud of our first windows machinery which are working scince 40 years. We provide our partners and customers only machinery which can work more then min. of 10 years agelife and this is the difference between other machine manufacturer and Baertec. You will invest only one time in Baertec Machines, but every year also after maybe 40 years you will be proud of your Baertec Machines and other machine dealers and users of different competition companies will be shocked after they know the prices of our products. Highest quality machines for good fair prices with happy customers and a excellent After Sales Service is the most importent vision of Baertec.

Hi

My name is Heather Jackson from UAE,

80/100 day want to produce window, I need by how machines,

I’m waiting for your comments,

Wood machines ind.trd.co

TEL: +97154564873